HHIP 41010030 Surface Roughness Standards Composite Set Amazon.ca Industrial & Scientific

Surface roughness is used to measure the total spacing irregularity on the surface of a part. The lower the surface roughness value, the less irregular the surface. So when machinists and engineers talk about "surface finish", they often mean surface roughness.

19 Images Surface Roughness Chart

March 26, 2023 / 7 minutes of reading Surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. The term "surface finish" is not defined correctly and tends to be used interchangeably by product designers and engineers with surface roughness, surface texture and surface topography.

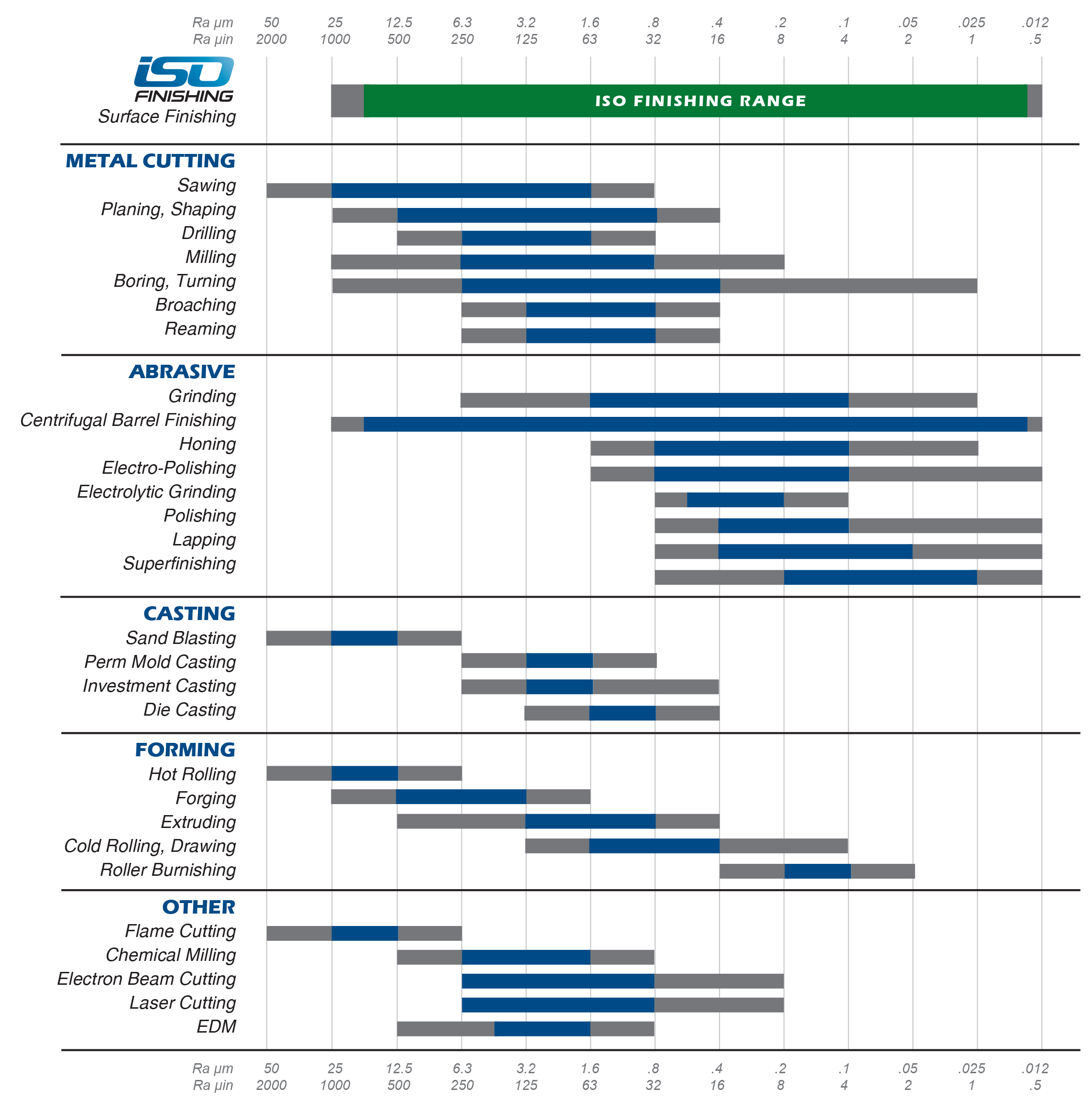

The Only Surface Finishing Chart (and Guide) You'll Ever Need

Surface roughness is an excellent predictor of mechanical part performance because irregularities on the surface can produce nucleation sites for fractures or corrosion. In tribology, rough surfaces wear faster and have greater friction coefficients than smooth surfaces.

Understand the Surface Roughness Chart and Make Great Parts

Get Surfacer Finsh based on Feedrate and Insert Radius, or get the needed Feedrate/Radius combinaion to achived a desired Ra.

Surface Roughness Chart Understanding Surface Finishes RapidDirect

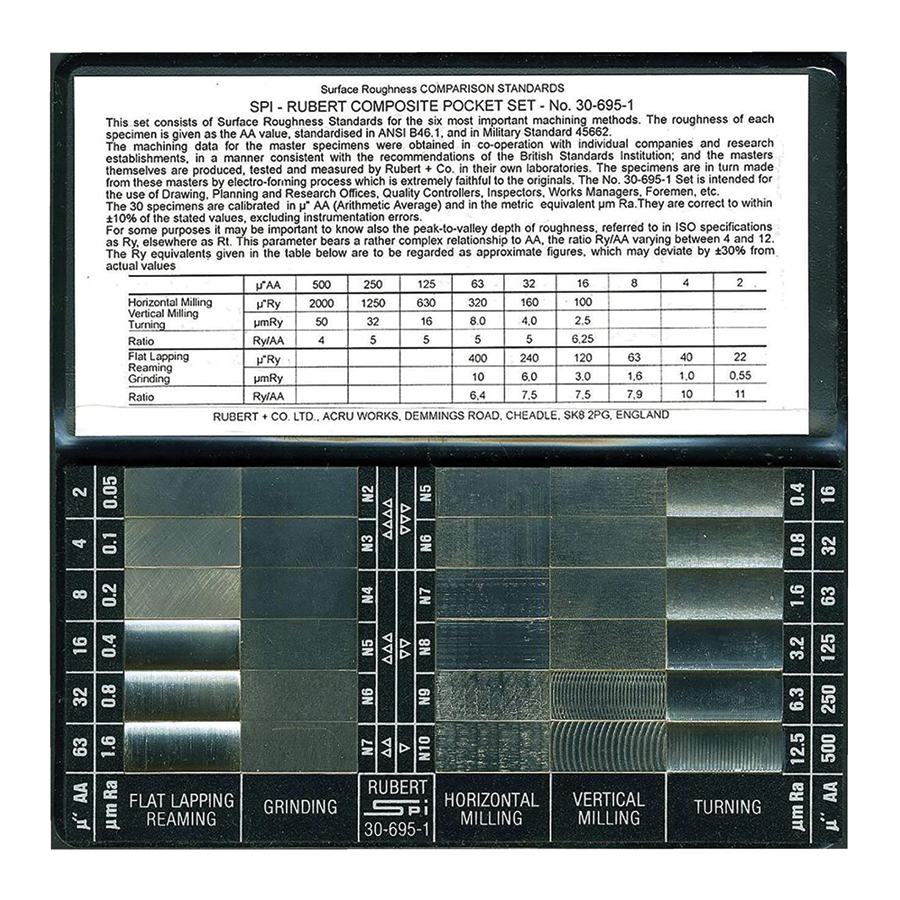

Surface Roughness can be measured by manual comparison against a "surface roughness comparator" (a sample of known surface roughness), but more generally a surface profile measurement is made with a profilometer. These can be of the contact variety (typically a diamond stylus) or optical (e.g.: a white light interferometer or laser scanning confocal microscope).

Data Chart for Surface Roughness Testing Download Table

Surface roughness, often shortened to roughness, is a component of surface finish (surface texture). It is quantified by the deviations in the direction of the normal vector of a real surface from its ideal form. If these deviations are large, the surface is rough; if they are small, the surface is smooth.

Surface Finishing Basics Fractory

Surface roughness, often shortened to roughness, is a component of surface texture. It is quantified by the deviations in the direction of the normal vector of a real surface from its ideal form. If these deviations are large, the surface is rough; if they are small, the surface is smooth.

Surface Finish Machinng Chart PDF PDF Surface Roughness Machining

The surface roughness chart is a concept that expresses the amount and extent of deviation of a surface from being perfectly flat. As it is practically impossible to manufacture a completely flat surface on the microscopic level, every surface has a certain value of roughness that can be measured with the use of a profilometer.

SurfaceRoughness of Parts to be Vacuum Brazed

The term "surface finish" usually refers to the level of polishing or texturing applied to the surface of a part or component. One of the surface texture parameters is surface roughness. These parameters quantify surface finishing features to regulate the manufacturing process or forecast a component's behavior during use. Surface Finish Parameters

Surface Roughness Chart Comparison ISO Finishing

Surface roughness is a measure of finely spaced surface irregularities. Surface roughness is usually what machinists refer to when talking about "surface finish." When talking about all three characteristics, they may use the term "Surface Texture" more properly. Waviness

Surface roughness values according to test variables. Download Table

The surface roughness is the measure of the total spaced irregularities on the surface. Whenever machinists talk about "surface finish," they often refer to surface roughness. Waviness refers to the warped surface whose spacing is greater than that of surface roughness length. Lay refers to the direction the predominant surface pattern takes.

Complete Surface Finish Chart, Symbols & Roughness Conversion Tables

Surface roughness is a measure of finely spaced surface irregularities. Surface roughness is usually what machinists refer to when talking about "surface finish." When talking about all three characteristics, they may use the term "Surface Texture" more properly. Waviness

Surface Finish Guide 5.5" x 8.5" Tool Box CNC Shop eBay in 2023 Surface roughness

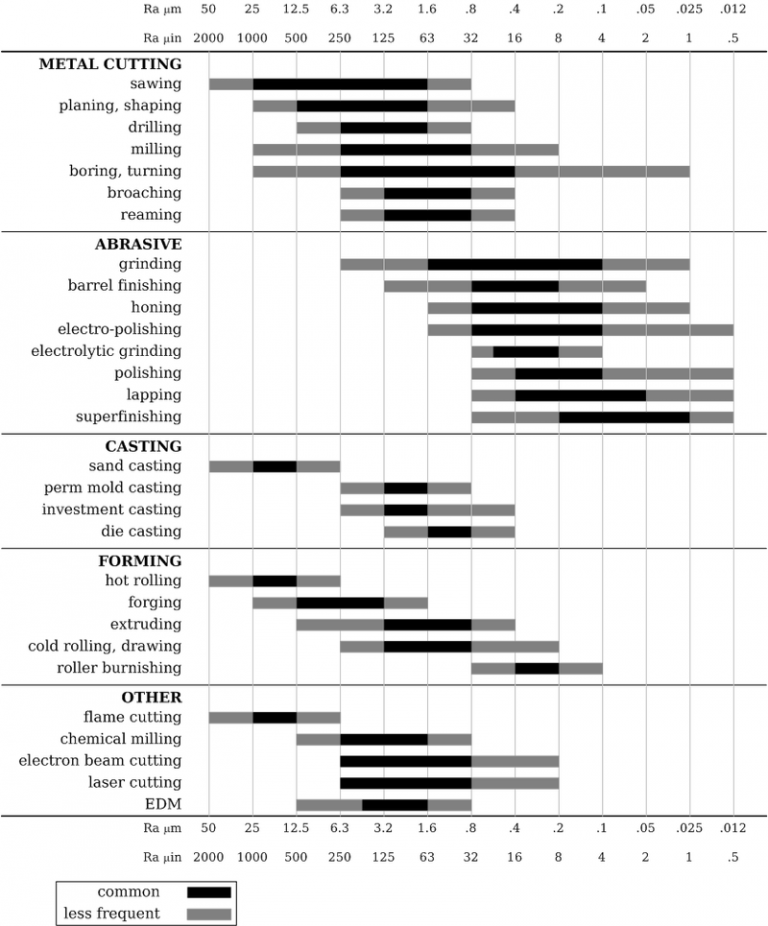

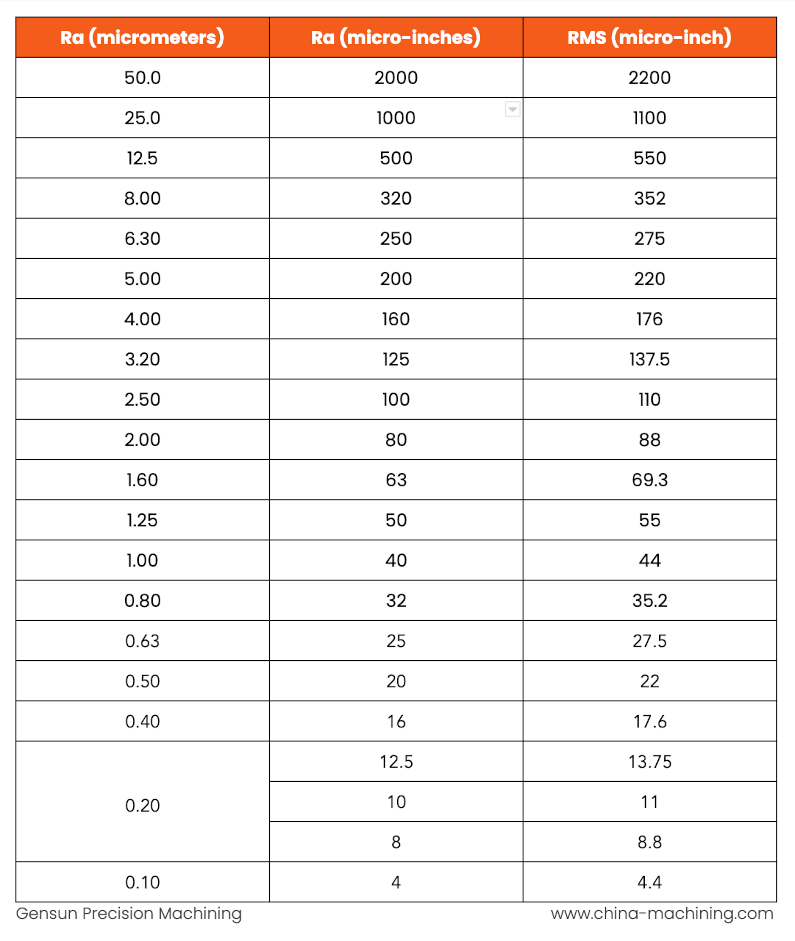

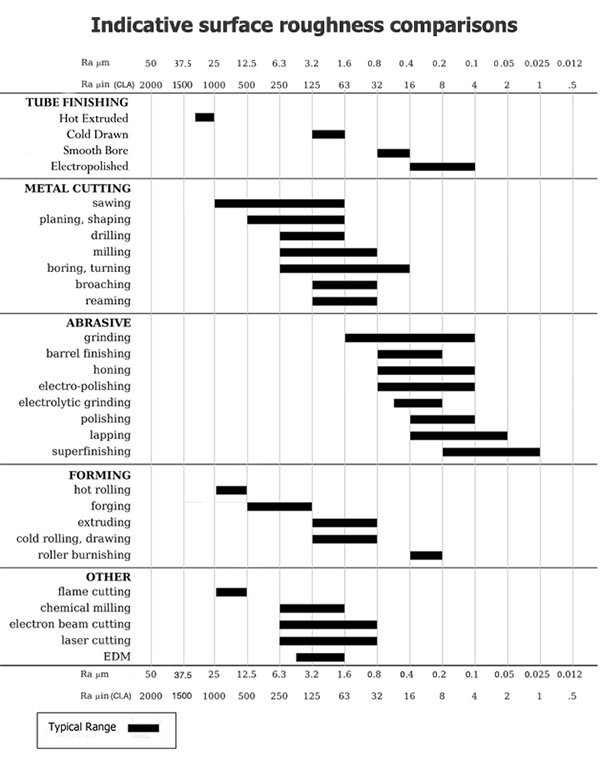

Surface Roughness Review The following charts and tables convert surface finish or roughness between selected industry standard units. Where: Ra = Roughness, average in micro-meters & micro-inches RMS = Root Mean Square in micro-inches CLA = Center Line average in micro-inches Rt = Roughness, total in microns N = New ISO (Grade) Scale numbers

Selecting right surface roughness for CNC machining Xometry Europe

The surface roughness chart is a valuable tool for surface roughness assessment, because it can be used to compare different parts, or to compare the same part before and after processing. You need to consider the purpose of the surface finish when selecting surface roughness parameters. If you have any questions about surface finish or surface.

Surface Finish Cross Reference Chart

What are Surface Roughness Terms and Symbols? Ra - Average Area Roughness Rmax - Vertical Distance from Highest Peak to Lowest Valley Rz - Average Maximum Height of the Profile ISO Surface Finish Symbols and Callouts Surface Roughness Chart Surface Finish Conversion Chart Conclusion FAQs What is Meant by Surface Finish?

Measured and the Predicted Values of Surface Roughness (Ra and Rz) and... Download Table

Conversion charts for surface roughness units, abrasive grits, and roughness grade numbers facilitate easy comparison and understanding of surface finish values. Additionally, practical tips such as adjusting feeds and speeds, using appropriate tooling, considering cutting parameters, and employing advanced machining techniques contribute to.